Mission and Values

Established in 1984, Longtex Rubber Industry has been a trusted manufacturer and exporter of high-quality rubber threads from Thailand to customers around the world. Guided by our commitment to quality, reliability, and continuous improvement, we strive to deliver products that meet customer requirements with consistency and precision.

Through advanced manufacturing technology, sustainable operations, and a culture of ongoing development, we ensure every meter of thread reflects our promises of high quality, on-time delivery, and value you can rely on.

Quality Policy

"Maintain High Quality Standards, Ensure Timely Delivery, Offer Fair Pricing, Meet Customer Needs, and Strive for Continuous Improvement."

Production Capacity

Longtex takes pride in its rich history and expertise in manufacturing extruded rubber threads. Since our establishment in 1984, we have grown exponentially, evolving from a production capacity of 200 tons per month to an impressive 1,500 tons per month. This remarkable expansion is a testament to our dedication to continuous improvement and meeting the growing demands of the market.

Research and Development

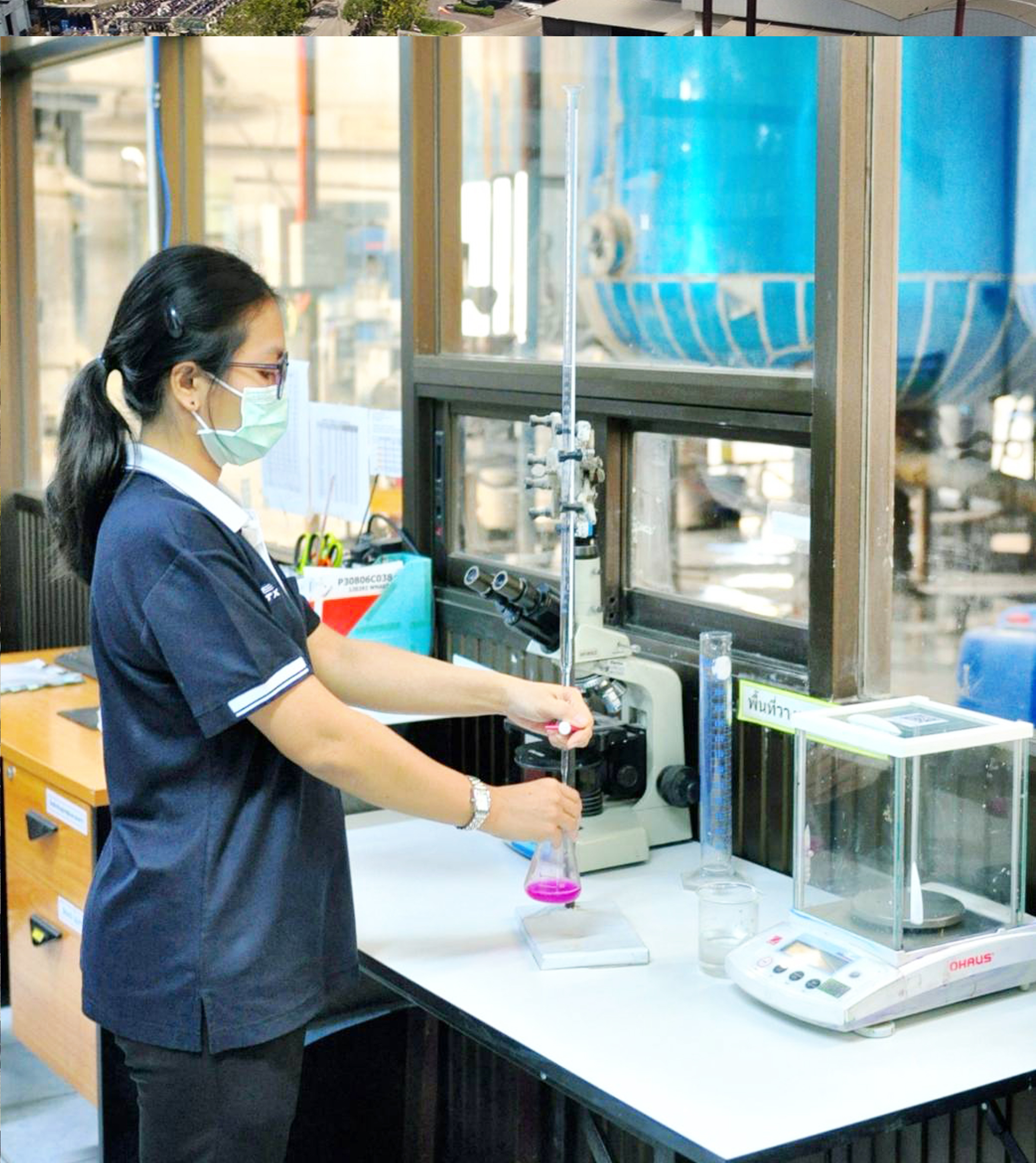

At Longtex Rubber Industry, our manufacturing capabilities are driven by our excellent teams, who possess deep technical knowledge and expertise. Our experienced professionals are equipped with a profound understanding of rubber thread manufacturing techniques, enabling us to produce superior products that consistently meet or exceed customer expectations. We foster a culture of flexibility and innovation, allowing us to adapt to evolving market trends and offer customized solutions to our valued clients.

International Standards

We attribute our success to a relentless pursuit of quality in every aspect of our operations. Our commitment to enhancing product quality has resulted in the establishment of a robust quality management system. We are proud to hold the prestigious OkeoTex certificate, which ensures that our rubber threads meet stringent international standards for safety and sustainability. Furthermore, we conduct various tests upon customer demands to provide tailored solutions that meet specific requirements.

Go Green

At Longtex, we strive to minimize our environmental footprint and maximizing positive impact. We are now integrating the use of renewable energy such as solar power and biogas generator into our production process to become more energy efficient. By harnessing power from the sun along with converting our production waste into electricity, we are able to reduce our carbon footprint and contribute to a cleaner and greener planet. Join us in our journey towards a greener and more sustainable future!